Spray Hood and Dodgers

Contents

Dodgers

My Dodgers suffered major "flogging" damage last year. Close inspection indicated they were beyond repair; the canvas was failing along the seams so new dodgers seemed like the only way forward.

After some research it seemed like it was possible to use our old "Jones CB" sewing machine to make some new ones. In fact, on further reading, older sewing machines like the Jones and Singer seemed preferable to more modern kit that use plastic gears and lacked the "oomph" of the older machines.

If, like me, you don't use the sewing machine often this is a good time to make sure that all the moving parts are greased properly.

What you're going to need

Sewing Machine

Thread

Needles & Pins

Seam Ripper

Scissors

Eyelets

Eyelet Tool

Chalk

Canvas

Stiffening Material

The Material

Acrylic canvas is the best material. I bought PU coated acrylic canvas (coated with Polyurethane) which was a mistake; uncoated would have been better and slightly cheaper. But having got it I decided to proceed.

My original dodgers also had pieces of pvc located where the dodger would rub against the steel uprights of the pushpit.

There was also pvc re-inforcing wherever an eyelet went through the material; this seemed a good idea and worth replicating.

Needles and Thread

There are two weights of polyester thread that you can use V69 and V92. These are the best to use as they have good resistance to Ultra Violet (UV) and are very strong. These are generally used with a size 16 and 18 needle respectively. I decided on the heavier weight (V92) for strength. I just bought 1oz of the thread initially to see how I got on. If you're worried about the straightness of your stitching (like me) it's worth getting thread the same colour as the material.

I also bought two packs of size 18 needles. It's reckoned that a needle has a working life of about 8hours much less on the heavy material we will be sewing. At the first sign of trouble try changing the needle.

One of the characteristics of both these threads is that it needs to be pulled of the top of the reel unlike a conventional cotton thread that feeds at right angles. To facilitate this I made a feeder out of piece and wood and a coat hanger to allow the thread to be pulled off the top of the reel.

Brass Eyelets

There are two types of eyelet available, with and without "spurs". The spurs engage with the material and provide a more secure fixing.

The spurless type are marginally cheaper but really not worth bothering with.

I bought a steel die here SDProducts and 100 3/8" spur eyelets.

The die is basically two pieces of steel that you put the eyelet between and clout with a hammer.

Tension Headaches: Setting up the Sewing Machine

If you don't use the sewing machine very often it really is worth making sure that you've got everything set up correctly. It's so easy to misthread the machine or bobbin or even put the needle in the wrong way round in which case nothing will work.

Take an off cut of material and try to sew few stitches. Does it look ok front and back? In all likelihood it won't. If you need to make an adjustment on the tension, just do a quarter turn at a time, sew a few stitches and review the outcome. It really is a process of trial and error but eventually you will find the setting that works. Take your time on this and don't lose heart.

Once you think you have it, double over the material and sew again. Still good? Double again and sew some more. If you can sew through 4 thicknesses of canvass, you're there. Lastly, if you're using any other "stiffening" material as well take an offcut of that and sew to the canvas. Still all good? I think we're done....

Dimensions

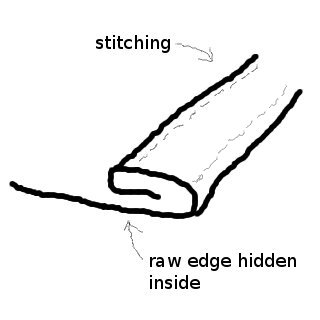

We've just going to be doing a "double rubbed hem" all round our rectangle of canvas. So if we allow 2cm for the "inside" turnover and another 5cm for the "outside" we can add 14cm (2X7) to our desired length and 14cm (2X7)to our desired width. So, for example, if our final dimensions need to be 2200 X 600 we would start out with a piece of fabric 2214 X 614.

Don't be tempted to try to make your hems much narrower than 2cm; acrylic canvas is very stiff and narrow hems are very fiddly to try and tuck under to sew.

And this point it's probably worth taking a piece of scrap and trying to make a hem along one edge.

References

Don Casey "This Old boat"