Difference between revisions of "Centaur"

(→Maintenance and Repair) |

(→Centaur Statistics) |

||

| (74 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

==Introduction== | ==Introduction== | ||

| − | First shown at the 1969 London Boat Show the Centaur production run reached 2,440 before the design was | + | First shown at the 1969 London Boat Show the Centaur production run reached 2,440 before the design was replaced by the Griffon in 1980. A variety of engines were origianally fitted with the 25hp Volvo MD2B and 23hp MDIIC being the most popular. |

| + | |||

== Centaur Statistics == | == Centaur Statistics == | ||

{| border="1" style="border-collapse: collapse; border-width: 1px; border-style: solid; border-color: #000" | {| border="1" style="border-collapse: collapse; border-width: 1px; border-style: solid; border-color: #000" | ||

|- | |- | ||

| − | |Designer:|| Laurent Giles ||rowspan=" | + | |Designer:|| Laurent Giles ||rowspan="22"| [[File:flora.jpg|350px |CR 1871 Flora, a 1977 Centaur entering Queenborough in June 2011 on a WOA East Coast Group Meet]] |

|- | |- | ||

|Keel:||Twin | |Keel:||Twin | ||

| Line 18: | Line 19: | ||

|- | |- | ||

|Draft (feet):|| 3' 0" | |Draft (feet):|| 3' 0" | ||

| + | |- | ||

| + | |Centaur Keel Width:||Width at leading edge 78", | ||

| + | Width at trailing edge 83", | ||

| + | |||

| + | Length 64" | ||

|- | |- | ||

|Displacement (lb):|| 6,700 | |Displacement (lb):|| 6,700 | ||

| Line 36: | Line 42: | ||

|- | |- | ||

|No 1 Jib (sq. feet):||133 | |No 1 Jib (sq. feet):||133 | ||

| + | |- | ||

| + | |Mast Height (m):||9.44 | ||

|- | |- | ||

|Sail ID:||CR | |Sail ID:||CR | ||

| Line 45: | Line 53: | ||

|Number Built:|| 2444 | |Number Built:|| 2444 | ||

|} | |} | ||

| + | |||

| + | ==Centaur Brochures== | ||

| + | Westerly Centaur Brochure here: [[Westerly Brochures]] | ||

| + | |||

| + | ==Buying Guide== | ||

| + | Thinking of buying a Centaur ? Find all you need to know here:[[File:CENTAUR_PURCHASE_ADVICE.pdf]] Paul Shave's Article Buying a Centaur | ||

== The Centaur Definitive Guide== | == The Centaur Definitive Guide== | ||

| − | |||

| − | ==[[Centaur Maintenance and | + | (First published in WOA magazine No. 51, Winter 1993) |

| + | |||

| + | Dennis Rayner’s designs had launched Westerly as a successful company, but by 1967 it was felt that fresh ideas were needed for a new range for the 1970’s. Jack Giles of Laurent Giles had recently launched "Bluebird of Thorne", a 50 foot twin keeler, for which he had done extensive tank testings. The tank testings decided it; he was the man to approach for state of the art twin keel designs. | ||

| + | |||

| + | The first effort was a bit of a disaster, since Laurent Giles had come up with what amounted to a development of the existing Westerly 25, which David Sanders thought was "all curves and no substance." David Sanders was very disappointed and said so to Jack Giles who immediately perked up and said "so you want a proper yacht?" | ||

| + | |||

| + | At this stage I can do no better than to produce the words of Jack Giles from his press release of March 1969: | ||

| + | |||

| + | ''Westerly Centaur'' | ||

| + | L.0.A.: 26ft. | ||

| + | L.W.L.: 21ft. 4ins. | ||

| + | Beam: 8ft. 5ins. | ||

| + | Draft: 3ft. | ||

| + | Working sail area: 341sq ft. | ||

| + | T.M.: 6 tons | ||

| + | Designers: Laurent Giles & Partners Ltd. | ||

| + | Builders: Westerly Marine Constructions Ltd. | ||

| + | |||

| + | |||

| + | ''To be commissioned to design for Westerly Marine was indeed a challenge. With the resources of their own Research Department allied to a highly developed production line and a keen Buying Office there seemed to be a danger of too many outside pressures working on the Designers.'' | ||

| + | |||

| + | ''In practice we found that this was not so, providing trouble was taken to appreciate and allot priorities to the requirements of the various departments concerned and provided we were prepared to work within a reasonable, but tight, time table.'' | ||

| + | |||

| + | ''The first result of this co-operation, the "Centaur", has a very low waterline over beam coefficient, a clean canoe body and twin bilge keels of aero-foil section.'' | ||

| + | |||

| + | ''The power installation has its propeller working in clear water and the balanced skegiess spade rudder provides ample control under sail or power.'' | ||

| + | |||

| + | ''Under sail the boat performs remarkably well to windward at a very modest angle of heel and under power did all that was expected of her and, in addition, showed unusually good handling characteristics when going astern.'' | ||

| + | |||

| + | ''The layout below decks is spacious for a boat of only 26 ft, overall having four comfortable 6ft. 6in. berths, a separate toilet compartment and a dinette arrangement which can be converted into an additional double bunk. Despite the space below decks, there is still a 6ft. 6in. self-draining cockpit, a feature of the boat which has appealed to the American market to which an appreciable number of "Centaurs" have already been exported. 20.3.69 | ||

| + | '' | ||

| + | |||

| + | The Centaur was officially launched at the London Boat Show 1969, and was an immediate hit worldwide, as can be seen from the press release. She was, and is, the perfect family yacht for all the reasons that Jack Giles outlined, but also because she was reasonably priced, and thoroughly well made. On the subject of maintenance and value, it is particularly important to have a steady replacement programme for any yacht so that her equipment, such as sprayhood, sails and instrumentation, is not dreadfully out of date or simply "clapped out." On the other hand, it is important to guard against the thought that spending £2,500 on vertical roller reefing will add significantly to the boat’s value. | ||

| + | |||

| + | ==More Photos== | ||

| + | [[File:Centaur-Charis-32TD66-3.jpg|800px]] | ||

| + | |||

| + | [[File:Centaur-Viento-Seco-1.jpg|800px]] | ||

| + | |||

| + | [[File:Centaur-Spartacus-S8620-1.jpg|800px]] | ||

| + | |||

| + | [[File:Centaur Whitev-Lady-1-1.jpg|800px]] | ||

| + | |||

| + | [[File:Centaur-Sentoray.jpg|800px]] | ||

| + | |||

| + | ==Maintenance, Repair and Upgrades== | ||

| + | |||

| + | [[Upgrading to an Electric Windlass|Fitting a Quick Genius 12v windlass to a Centaur]] | ||

| − | + | [[Centaur Sink]] | |

| − | + | [[Media:ST176_single_line_reefing_Dec_2011.pdf| Fitting Barton Single line reefing from Sailing Today Dec 2011]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[ | + | [[Centaur Main Cabin Wall Cupboards]] |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[DIY cockpit seating teak substitute]] | |

| − | |||

| − | |||

| − | |||

| − | [[ | + | [[Centaur Cutless Bearing Removal and Replacement]] |

| − | |||

| − | |||

| − | |||

| − | [[ | + | [[Removing the Propeller Shaft]] |

| − | + | [[Centaur Rudder bearings]] | |

| − | [[ | + | [[Removing a Centaur Water Tank]] |

| − | + | Presentation by Winston Waller to East Coast Group Winter Workshop 2013 about how he treated his Centaur hull [[http://www.westerly-owners.co.uk/documents/pptdocs/EpoxyTreatmentCentaurHull.ppt Epoxy Treatment of Centaur Hull]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Removing a MD2B from a Centaur [http://www.westerly-centaur.co.uk/centaur-md2b- Pictures of Removal] | |

| − | + | [[Raising a Centaur Mast using a Gin Pole]] | |

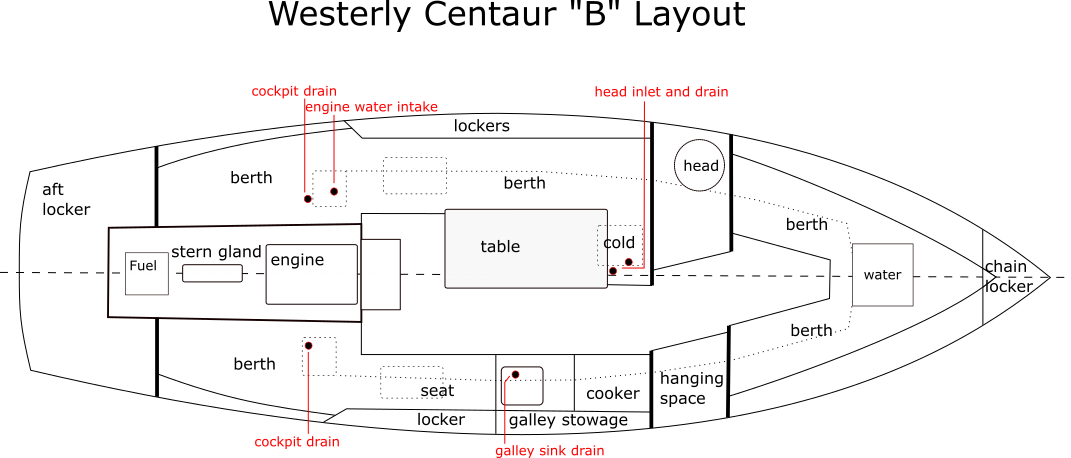

| − | + | ==Contributed Graphics and Plans== | |

| − | [ | + | [[File:Centaur-b.png | Centaur B Layout]] |

| + | * [[Media:Centaur-b.png | Centaur B Layout (PNG)]] | ||

| + | * [[Media:Centaur-b.pdf | Centaur B Layout (PDF)]] | ||

==References== | ==References== | ||

| − | + | ===Official Westerly Documents=== | |

| + | |||

| + | [[Media:112808408-Centaur-Manual.pdf | Centaur Manual]] | ||

| − | + | ===Magazine Publications=== | |

| − | [[Centaur | + | * [https://www.pbo.co.uk/publication/pbo/may-2019 PBO Centaur 50th Rally Article PBO No 638 May 2019] |

| + | * [http://www.yachtingmonthly.com/reviews/yacht-reviews/used-boat-westerly-Centaur Yachting Monthly June 2016] | ||

| + | * PBO Centaur Ketch Article PBO No 403 July 2000 (Available as a reprint) | ||

| + | * PBO Centaur Article PBO No 354 June 1996 (Available as a reprint) | ||

| − | == | + | ===Web sites and blogs=== |

| − | + | * [http://laurentgilesarchive.com/product/westerly-centaur/ Laurent Giles Archive - Plans/Notes for the Centaur] | |

| + | * [http://www.agentlemansyacht.com/ Roger Ball's blog about K391 - A Gentleman's Yacht] | ||

| + | * [https://centaurfree.home.blog Ian Norton's Centaur blog] | ||

| − | == | + | ===YouTube Channels and Videos=== |

| − | |||

| − | + | * [https://www.youtube.com/channel/UCnvPtZMOJhVzwR05VCokHNw The Sailing Dutchman] | |

| + | * [https://www.youtube.com/channel/UCv8LerszK9pFCG3bVzRrIYg Second Chance Sailing] | ||

| + | * [https://www.youtube.com/user/Captainbirdseye100 Steve Jenkinson] | ||

| + | * [https://www.youtube.com/watch?v=zpjJS59Lr_8 Easy Sailor - Sailing to Ostend on a Westerly Centaur] | ||

| + | * [https://www.youtube.com/watch?v=IQhKYrjGJEc Oli Banks - Centaur POV Tour] | ||

[[Main Page|Back to the Main Page]] | [[Main Page|Back to the Main Page]] | ||

Latest revision as of 18:12, 28 June 2020

Contents

Introduction

First shown at the 1969 London Boat Show the Centaur production run reached 2,440 before the design was replaced by the Griffon in 1980. A variety of engines were origianally fitted with the 25hp Volvo MD2B and 23hp MDIIC being the most popular.

Centaur Statistics

Centaur Brochures

Westerly Centaur Brochure here: Westerly Brochures

Buying Guide

Thinking of buying a Centaur ? Find all you need to know here:File:CENTAUR PURCHASE ADVICE.pdf Paul Shave's Article Buying a Centaur

The Centaur Definitive Guide

(First published in WOA magazine No. 51, Winter 1993)

Dennis Rayner’s designs had launched Westerly as a successful company, but by 1967 it was felt that fresh ideas were needed for a new range for the 1970’s. Jack Giles of Laurent Giles had recently launched "Bluebird of Thorne", a 50 foot twin keeler, for which he had done extensive tank testings. The tank testings decided it; he was the man to approach for state of the art twin keel designs.

The first effort was a bit of a disaster, since Laurent Giles had come up with what amounted to a development of the existing Westerly 25, which David Sanders thought was "all curves and no substance." David Sanders was very disappointed and said so to Jack Giles who immediately perked up and said "so you want a proper yacht?"

At this stage I can do no better than to produce the words of Jack Giles from his press release of March 1969:

Westerly Centaur L.0.A.: 26ft. L.W.L.: 21ft. 4ins. Beam: 8ft. 5ins. Draft: 3ft. Working sail area: 341sq ft. T.M.: 6 tons Designers: Laurent Giles & Partners Ltd. Builders: Westerly Marine Constructions Ltd.

To be commissioned to design for Westerly Marine was indeed a challenge. With the resources of their own Research Department allied to a highly developed production line and a keen Buying Office there seemed to be a danger of too many outside pressures working on the Designers.

In practice we found that this was not so, providing trouble was taken to appreciate and allot priorities to the requirements of the various departments concerned and provided we were prepared to work within a reasonable, but tight, time table.

The first result of this co-operation, the "Centaur", has a very low waterline over beam coefficient, a clean canoe body and twin bilge keels of aero-foil section.

The power installation has its propeller working in clear water and the balanced skegiess spade rudder provides ample control under sail or power.

Under sail the boat performs remarkably well to windward at a very modest angle of heel and under power did all that was expected of her and, in addition, showed unusually good handling characteristics when going astern.

The layout below decks is spacious for a boat of only 26 ft, overall having four comfortable 6ft. 6in. berths, a separate toilet compartment and a dinette arrangement which can be converted into an additional double bunk. Despite the space below decks, there is still a 6ft. 6in. self-draining cockpit, a feature of the boat which has appealed to the American market to which an appreciable number of "Centaurs" have already been exported. 20.3.69

The Centaur was officially launched at the London Boat Show 1969, and was an immediate hit worldwide, as can be seen from the press release. She was, and is, the perfect family yacht for all the reasons that Jack Giles outlined, but also because she was reasonably priced, and thoroughly well made. On the subject of maintenance and value, it is particularly important to have a steady replacement programme for any yacht so that her equipment, such as sprayhood, sails and instrumentation, is not dreadfully out of date or simply "clapped out." On the other hand, it is important to guard against the thought that spending £2,500 on vertical roller reefing will add significantly to the boat’s value.

More Photos

Maintenance, Repair and Upgrades

Fitting a Quick Genius 12v windlass to a Centaur

Fitting Barton Single line reefing from Sailing Today Dec 2011

Centaur Main Cabin Wall Cupboards

DIY cockpit seating teak substitute

Centaur Cutless Bearing Removal and Replacement

Presentation by Winston Waller to East Coast Group Winter Workshop 2013 about how he treated his Centaur hull [Epoxy Treatment of Centaur Hull]

Removing a MD2B from a Centaur Pictures of Removal

Raising a Centaur Mast using a Gin Pole

Contributed Graphics and Plans

References

Official Westerly Documents

Magazine Publications

- PBO Centaur 50th Rally Article PBO No 638 May 2019

- Yachting Monthly June 2016

- PBO Centaur Ketch Article PBO No 403 July 2000 (Available as a reprint)

- PBO Centaur Article PBO No 354 June 1996 (Available as a reprint)

Web sites and blogs

- Laurent Giles Archive - Plans/Notes for the Centaur

- Roger Ball's blog about K391 - A Gentleman's Yacht

- Ian Norton's Centaur blog